Dr. Garth Hatch discusses Tri Hawk’s Talon series of burs

As an endodontist and practice management consultant, I’m always looking for technological breakthroughs that lead to greater efficiency, safety, and predictability. In the modern world, we often think of big advances in technology coming in the shape of electronics and fancy machines, but often the things that make the biggest difference come in the smallest and least thought of aspects of our jobs. In this case, we are looking at the dental burs that all dentists use and are incredibly important to endodontics. Most endodontists have experienced the stress that occurs when a bur breaks during an apicoectomy or the difficulty of accessing through crowns efficiently yet still preserving the porcelain to avoid costly crown replacement. Selecting the right bur for the right job can truly elevate the level of predictability possible during surgical procedures, endo-access, and more. Tri Hawk’s Talon series of burs is just such a technological breakthrough that can truly enhance your practice.

Equipment efficiency — a pillar of professional dentistry

Within my operatory, I expect to have reliable results based on my selection of equipment, technique, and staff to mitigate risk. One of the immediate points of contact with the patient in most endodontic procedures occurs with the use of dental burs. When burs break, it almost always occurs at the union between the cutting bur and shank as this is typically the weakest junction in the bur. My own personal frustration with having burs break during treatment, especially during surgeries, is what led me to try the Talon burs. Although any bur on the market today can break under enough torque or load, the Tri Hawk Talon burs are extremely fracture resistant due to their unique steel blend and a proprietary welding technique.

When I tried the Talon burs for the first time, I was extremely impressed with their strength and cutting efficiency and immediately became a big fan. I highly recommend single-use burs with any surgical procedure, including the Tri Hawk Talon burs. This ensures the bur is sharp, clean, strong, and will function at its best every time it comes out of the package. The Tri Hawk line of burs can be utilized for many different dental applications and procedures. Here are some of the most common.

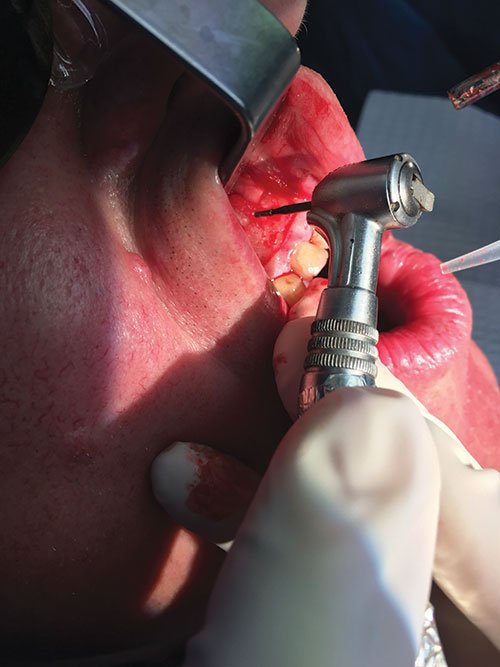

Apicoectomies

If you perform apicoectomies on a regular basis, you’ve likely experienced the gut-wrenching feeling of having a surgical bur break while accessing through bone or retro-prepping the apex. This bur breakage isn’t just an inconvenience, but potentially can cause major complications if the broken bur ends up in the sinus, is aspirated, or lodged underneath the surgical flap where locating and retrieval would be difficult. Costly and challenging surgical procedures may be required to remove the bur tip depending on the situation. Any of these scenarios could harm the patient and lead to lawsuits or ill-will between the patient and health care provider.

Another major advantage of the Tri Hawk Talon surgical burs is their length and extreme cutting efficiency. The Talon 12 Surgical brings a 25-mm length to the hyperbolic shape, exacting all the strength and speed that you would expect from a standard length. The shape also offers easy evacuation of bio-material, so that cutting ability and visibility remain true throughout the procedure. The Talon cutting efficiency also reduces chatter while cutting through root apices and bone to help reduce microfractures.

Endo-access hole through PFM

Preserving a crown means avoiding expensive replacement cost. The Talon 10 has no crosscut teeth, which reduces micro-factures in porcelain-fused-to-metal crowns and possible fracturing of a porcelain cusp. This reduction in microfractures also helps to preserve the porcelain margin around the hole. Once the access hole is made vertically, access can be expanded using the horizontal blades. There’s no changing of burs or the need to remove the bur from the access hole, which improves speed and treatment efficiency.

Endo-access hole through zirconia

Zirconium crowns can be particularly difficult to access through due to the hardness of the material. For these crowns, it is necessary to switch to a diamond bur. I recommend using Tri Hawk Diamond round burs in a coarse grit. There are other burs on the market that are comparable in cutting efficiency to the coarse round burs, but I’ve found that one or two coarse burs are a better value than some of the more costly burs designed for cutting zirconium.

Crown and bridge removal

This is a common procedure that can take an excessive amount of chair time. Removing a hardened crown typically means leading with a diamond and switching mid-procedure to a carbide. The Talon 12 reduces the steps down to one. See the video at https://bit.do/Talon. There is no need for more than one bur. Clean and consistent cutting, sections both porcelain and metal with one clean sweep.

Implants

The growing demand for implants from both patients and dentists alike have ushered the need for the Talon 14 Surgical. The efficiency of the larger bur head is prized by dentists in our clinic for quick and efficient cutting ability. It cuts as fast during the last 10 seconds as the first 10 seconds. It has proven to be a great tool for sectioning and removing teeth due to the ability to penetrate down and sideways at the same time.

In addition to these features, the Talon series of burs will trim any type of post or abutment including titanium with little effort.

Important notes on using this incredible technology that Tri Hawk offers

Tri Hawk states that “The Tri Hawk Talon Line of burs offers versatile solutions to modern dentistry. Its unique hyperbolic design offers an aggressive rake angle that carves through any hardened material with ease. With both horizontal and vertical blades, the Talon can easily cut through any resistant material such as metal alloys, semi-precious metal, amalgam, porcelain-fused-to-metal or bone.“ This is all well and good, but to get these kinds of results, you do need to use the product properly. There are two secrets that I have found are effective and Tri Hawk recommends in order to cut most efficiently through all of the materials that Tri Hawk lists: Give the bur a little bit of a tilt, and use a very light touch.

In the use of this product, the best results have been achieved by giving the bur a little tilt. By cutting at an angle of 30 to 40 degrees, you are taking advantage of both end-cut and side-cut capability at the same time and engaging the most aggressive cutting edges. The Talon cuts through its target like a hot knife through butter. There is a great video on line at https://bit.do/trihawkburs that demonstrates this technique extremely well.

When using an aggressive cutting carbide bur like Tri Hawk’s Talon line, it is also very important to use a feather light touch; just let the bur do the work. Be firm in your grip so that you have good control over where you are cutting, but don’t apply any more pressure than what you need to start the cutting. This will give you both the best control and the fastest cutting speeds.

Not only does Tri-Hawk focus on performance, they also ship the burs in functional, convenient, easy-to-use hospital-style packaging. They want the Talon to offer its best performance every time you take it out of its package. They promote “single-use” because it promotes patient comfort, speed, safety, and the dentist’s bottom line. A new and sharp bur means a faster more comfortable procedure, and prevents any patient-to-patient transmission of pathogens. This also means more patients seen on time, more referrals, and fewer potential complications.

Who Is Tri Hawk?

The strength of Tri Hawk burs is unparalleled. They are virtually unbreakable due to their special steel blend and a proprietary welding process that facilitates a stronger design — the burs are made stronger! Industry wide, most burs are tested 2 to 3 times throughout production. Tri Hawk burs must pass eight stringent quality control tests throughout the production process before being deemed high enough quality for their customers.

Tri Hawk has been selling burs since 1969 and manufacturing dental burs since 1986. Gustel Fischer, Tri Hawk’s owner and president, talks about the company as having been “on a never-ending quest for the perfect bur.” This quest for perfection shows in their product, which include regular carbide burs, surgical carbide burs, Diamond burs, and the Talon line of crown-cutting carbide burs.

This information was provided by Tri Hawk.

Stay Relevant With Endodontic Practice US

Join our email list for CE courses and webinars, articles and more..